The development of robots and artificial intelligence has for the past few years greatly impacted on job security and employee retention as robots are taking over the work that humans have been doing for time immemorial. This replacement becomes more imminent as robots are also branching into other sectors and people are now wary about what the future holds for their posts and positions in the workplace.

For example, hospital jobs that do not require a Bachelor’s degree are quickly disappearing. Positions such as licensed practical nurses and medical-records clerks are being eliminated or pushed out of hospitals into lower-paying corners of the field such as nursing homes. Meanwhile, positions that were once an accessible first rung on the career ladder, such as registered nursing, increasingly require at least a Bachelor’s degree.

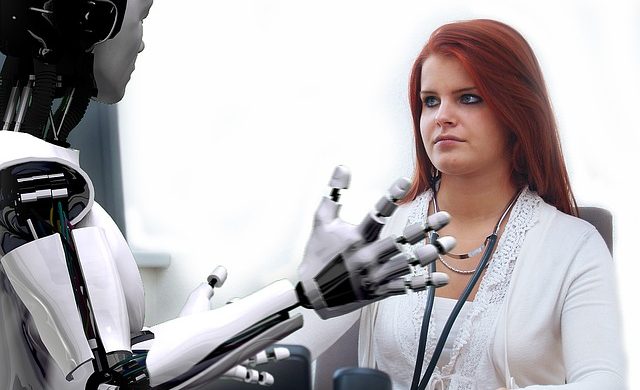

In a time of growing economic inequality, the elimination of these jobs seems discouraging. Robots can do some jobs better, cheaper, and faster than humans. They can transcribe and store information, help doctors and nurses diagnose their patients, and even allow lower-skilled health care workers to treat patients with less oversight from doctors and other higher-skilled workers.

Singularity Hub, a leading technology blog, reports that El Camino Hospital in Silicon Valley in 2014 was looking to cut expenses, so the hospital was looking into investing in 19 Aethon TUG robots. These smart carts can haul supplies around the hospital, making deliveries and pickups at a fraction of the costs of human workers. El Camino Hospital also announced that it would further be cutting costs by firing up to 140 workers from its two facilities in Los Gatos and Mountain View. According to a hospital administrator quoted in the Businessweek, the 19 TUGs perform $1 million of human labor/year, but only cost $350,000. This would mean a 65% reduction in labour costs.

One multi-tasker bot, from Momentum Machines, can make and flip a gourmet hamburger in 10 seconds and could soon replace an entire McDonalds crew. A manufacturing device from Universal Robots doesn’t just solder, paint, screw, glue, and grasp, it also builds new parts for itself when they wear out or bust. In 2015, Google won a patent to start building worker robots with personalities. In light of this, the workers in factories and technical industry have to brace themselves for early retirement and start planning ahead.

Oxford University researchers have estimated that 47 percent of U.S. jobs could be automated within the next two decades. And if even half that number is closer to the mark, workers are in for a rude awakening.Report finds 38% of US jobs will be automated by 2030 4 in 10 US jobs are at high risk of being replaced by robots. Other reports suggest 38% of US jobs will be automated by the early 2030. In addition to this, financials service positions are at high risk – 61% will be replaced. Meanwhile, only 30% of jobs in the U.K. are similarly endangered. The same level of risk applies to only 21% of positions in Japan.

Driverless vehicles could threaten the jobs of millions who drive trucks and taxis. Others believe it will not happen for years.

In Australia and other countries, driverless trucks move large loads of dirt and ore in mines. The trucks can operate in the mines because there are few other vehicles there. But it will be more difficult for vehicles to operate on roads where there are many other vehicles. An increase in industrial robots means fewer humans will have high-paying manufacturing jobs.

Machines in general — are substituting for people. “Technophobes”—people who fear robots, artificial intelligence and new technology that they don’t understand—are much more likely to be afraid of losing their jobs to technology and to suffer anxiety-related mental health issues, a Baylor University study found.

More than a third of those in the study fit its definition of “technophobe” and are more fearful of automation that could lead to job displacement than they are of potentially threatening or dangerous circumstances such as romantic rejection, public speaking and police brutality, according to the study. In 2016, a German factory manned largely by robots made its first 500 pairs of Adidas running shoes. Called the “Speedfactory,” it will still use humans for parts of the assembly process. Adidas says it’s working toward full automation.

For companies, this presents a challenge in that they need to constantly embark on refresher courses for their employees so that they stay attuned to various technological advancements. This in turn requires money and further increases the budget and expenditure. People will need training and qualification in order to develop and make this machinery and how only a limited number of people will be required

The question which then arises from all this is the fact that the world’s population is standing at 7 billion and counting. The unemployment rate is increasing and this means that the labour force and manpower to work is in surplus. Unfortunately, the problem is that there are no jobs for these people to work in. University graduates themselves are finding it difficult getting employed in the first place whilst others are getting retrenched all at the advent of technology in the workplace. The challenge is what can we do as the living breathing machines to alleviate the burden of retrenchment and unemployment in the face of being left by technology.

Article by Nelson Madzima.